| 126 South Turnpike Road Unit 2 Wallingford, CT 06492 |

|

Call Today! 203-265-4167   |

How Automated Laser Welding Can Save You Time and Money

Did you know? Companies that migrate to automated laser welding slash their production times by up to 40%—a game-changer in today’s ultra-competitive market. If you’re seeking a smarter way to meet tight deadlines, contain costs, and raise product quality, this guide will show how advanced laser system technology can help you transform your manufacturing approach. Dive in to discover practical examples, industry use cases, and actionable buyer tips—plus exactly how this tech can save your company real dollars.

The Power of Automated Laser Welding: Transforming Manufacturing Efficiency

-

Discover how automated laser welding systems are revolutionizing production time and operational costs with a compelling fact: Companies adopting automated laser welding have slashed production times by up to 40%. Here’s why businesses are switching to advanced laser welding solutions now.

Automated laser welding stands at the forefront of modern manufacturing, offering transformative benefits that go beyond incremental productivity gains. By harnessing a focused laser beam, companies achieve weld seams of exceptional precision at light-speed pace. This shift to advanced laser welding systems allows manufacturers not just to keep up with demand but to pull far ahead of competitors using conventional welding approaches.

One of the key drivers in this technological revolution is the proven reduction in production time—up to 40% according to industry benchmarks. Unlike traditional welding processes, automated systems require minimal labor intervention, reduce the risk of human error, and streamline the welding process for complex assemblies. The result? Increased throughput, consistent quality welds , and dramatic cost savings. It’s no wonder both large and small businesses are making the switch to these cutting-edge solutions now to future-proof their operations.

Unlocking Savings: How Automated Laser Welding Streamlines Your Workflow

Practical Examples of Automated Laser Welding in High-Volume Production

In real-world manufacturing, time truly is money. Automated laser welding is engineered for high-volume environments, where speed and reliability determine profitability. Take automotive production lines, for example: integrating a laser welding solution into chassis assembly means hundreds of precisely welded joints can be completed with minimal downtime. The heat source is contained to a focused beam, reducing distortion and allowing instant production ramp-up.

Another practical example can be found in electronics manufacturing. Here, delicate circuit boards require precise, repeatable joins that automated laser welding provides without degrading sensitive components. By automating these welding processes , companies improve product weld quality while reducing manual inspection and rework. In both scenarios, faster cycle times and lower rejection rates translate directly into significant cost savings and higher production yield.

Why Automated Laser Welding Outperforms Traditional Welding Systems

Automated laser welding is fundamentally more efficient than traditional systems such as arc welding, gas welding, or manual TIG and MIG. In these older techniques, processes are slower and often require continuous human monitoring and adjustment of parameters such as wire feed and heat settings. This not only ties up skilled operators but leads to variability in weld seam consistency and productivity bottlenecks.

In contrast, today’s advanced laser welding systems use precise computer controls and vision-guided units to manage every step of the welding process in real time. The result is a highly controlled, non-contact method that can join a wide variety of materials—from thin foils to thick steels and modern alloys—with unmatched repeatability. Integrating automation reduces manual labor costs, ensures consistent output, and delivers finer, stronger welds for demanding applications. Businesses quickly see the impact on their bottom line and operational efficiency.

Comparing Laser Welding Systems: Features, Flexibility, and Benefits

|

Welding System |

Speed |

Precision |

Operating Cost |

Materials Compatibility |

|---|---|---|---|---|

|

Automated Laser Welding |

Very High (up to 40% faster) |

Exceptional (±0.02mm) |

Low (energy- and labor-saving) |

Metals, polymers, alloys, thin/thick materials |

|

Hybrid Laser |

High |

High |

Medium |

Metals, select alloys |

|

Arc Welding |

Moderate |

Moderate |

Medium-High |

Metals, limited alloys |

|

Fiber Laser |

Very High |

Excellent |

Low |

High-tech metals, micro-welding, medical devices |

|

Traditional Welding Systems |

Slow-Moderate |

Variable |

Higher |

Basic metals |

Choosing between different welding systems —such as automated laser, hybrid laser, fiber laser, or arc welding—depends on your production goals. Automated laser welding stands out for its combination of high-speed operation, pinpoint accuracy, and wide materials compatibility, making it a preferred welding solution for forward-thinking manufacturers.

While arc welding is still common for traditional tasks, its precision and operational costs lag behind advanced laser system alternatives. Hybrid and fiber laser technologies push the envelope further, providing unique benefits for specific materials or micro-scale applications. Reviewing these capabilities helps businesses target more efficient, cost-effective, and quality weld production tailored to what matters most in their workflow.

How Laser Welding Systems Reduce Labor and Material Costs

Case Study: Saving Real Dollars with Automated Laser Welding Solutions

Automated laser welding solutions don’t just boost productivity—they fundamentally lower the cost structure of manufacturing. Take for instance a medium-sized precision machinery company that replaced traditional manual welding with a state-of-the-art laser welding system . Labor requirements fell dramatically: instead of four operators per line, a single technician now oversees multiple laser welding systems , each performing thousands of welds per shift with minimal supervision.

Material savings are equally impressive. Advanced laser beam controls ensure optimal energy delivery and exact heat placement, leading to less warping, fewer defective parts, and waste rates as low as 1%. Scrap metal and rejected assemblies become rare exceptions, not the norm. These tangible savings, combined with automatic quality checks and traceability, drive the rapid ROI reported across industries—from metal fabrication to medical device and electronics manufacturing.

"With automated laser welding, our throughput doubled and scrap rates fell below 1%. The ROI was achieved in just 11 months." – Plant Manager, Precision Metalworks

Exploring Advanced Laser System Technologies for Precise Results

Understanding the Laser Beam: Fiber Laser, Hybrid Laser, and More

A deeper understanding of laser system types unlocks more manufacturing advantages. The most common are fiber laser, hybrid laser, and CO2 laser technologies. Fiber laser units offer a slim, focused laser beam that excels at fast, fine welds—often used for high-value and micro-welding work in electronics, medical device assembly, and even additive manufacturing. Hybrid lasers blend the benefits of regular and fiber lasers with added arc welding features, giving the operator more flexibility in welding processes .

The key is precise beam control: automated systems use digital parameters to set weld seams , speeds, depths, and heat profiles. Because this control is software-based, transitioning between parts or materials only requires program tweaks instead of costly hardware changes. That’s why today’s laser welding solutions easily keep up with evolving production lines, helping you achieve tight tolerances and flawless finishes—no matter the complexity or geometry of the parts.

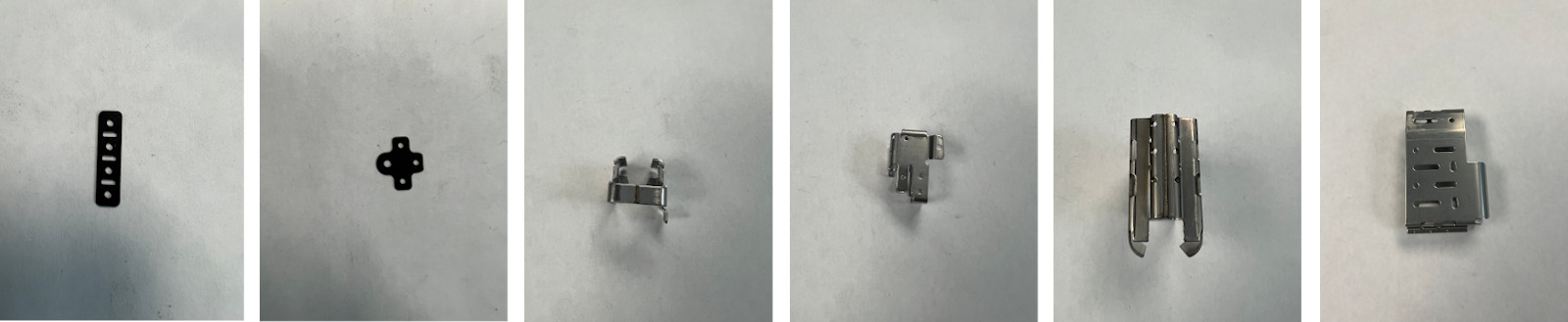

Advantages of Polymer Welding and Laser Cutting with Laser Systems

Beyond traditional metals, automated laser system technology has pushed into new frontiers such as polymer welding and advanced laser cutting . Polymer welding with lasers delivers precise, rapid joining for plastics and composite materials, supporting lightweight assemblies used in automotive, aerospace, and electronics. This method produces clean, strong joints without adhesives or fasteners, enhancing both the function and aesthetics of final products.

Laser cutting—using the same basic hardware platform but a different operational mode—enables ultra-fine, high-speed cutting of a range of materials: metals, polymers, ceramics, and advanced composites. Automated machine vision ensures each cut is repeatable and within micron-level tolerances, crucial for modern assembly and additive manufacturing workflows. For manufacturers seeking to combine welding and laser cutting in a single welding solution , today’s advanced systems deliver both under unified control.

Key Considerations for Choosing the Right Automated Laser Welding Solution

-

Checklist: What to look for in automated laser welding systems (software capabilities, integration with existing manufacturing lines, automation level, precision controls).

Selecting the best automated laser welding system for your operation starts with a clear needs assessment. Look for comprehensive software that allows for easy programming and rapid adjustments for new assembly types or material changes. Ensure the laser system is designed to integrate seamlessly with your current manufacturing lines, whether you use conveyors, robotic arms, or smart sensors. Automation level should match your throughput goals—choose systems that can operate with minimal human intervention for the greatest ROI.

Beyond hardware, evaluate the precision controls offered. The top systems let you fine-tune welding process parameters for everything from laser beam diameter to pulse width and energy intensity. Comprehensive quality weld monitoring, in-line vision inspection, and digital connectivity for Industry 4.0 environments position your facility for both current and future production needs. Take the time to check for comprehensive service support and future upgrades so your investment continues to pay dividends as technologies advance.

Video Demo: See Automated Laser Welding in Action

Nothing highlights the benefits of automated laser welding like seeing these systems in action. High-definition video demos show robots maneuvering components with pinpoint accuracy, lasers emitting streams of light as they join, cut, or shape metals and polymers with immaculate precision. Watching instant feedback from computer-controlled sensors, you can observe real-time adjustments that guarantee a perfect weld seam on every part. If you’re evaluating equipment, request video demos to see capabilities before you buy.

Real-World Applications: Where Automated Laser Welding Makes the Greatest Impact

From Automotive to Electronics—Industry Examples of Automated Laser Welding Implementation

Automated laser welding systems are revolutionizing the automotive sector, where advanced robot-guided units weld car chassis, battery tabs, and fuel rails faster—and with better strength—than ever before. In high-throughput automotive lines, repeatable weld quality is crucial for both safety and production volume. Advanced vision-guided robots armed with fiber laser and hybrid laser heads ensure each assembly meets rigorous standards, and digital traceability enables full part tracking from start to finish.

Transitioning to electronics manufacturing, automated laser welding benefits scale down to micro-precision. Here, delicate medical devices , pacemakers, semiconductor housings, and batteries are assembled with zero room for error. Because the laser beam delivers heat in a highly localized, non-contact fashion, manufacturers can avoid thermal damage and create intricate welds otherwise impossible with conventional welding systems. Across sectors, the range of applications continues to expand—and so do the competitive advantages for users.

What Are the Leading Automated Laser Welding Systems on the Market?

-

Trumpf TruLaser : Renowned for unmatched precision, robust build, rapid setup, and extensive safety features. Customer reviews praise reliability and software flexibility.

-

IPG Photonics Fiber Laser Series : Offers industry-leading efficiency for metals and polymers, low maintenance, and integrated remote monitoring. Customers cite uptime and service as standout elements.

-

Fanuc Robotic Laser Welding : Includes versatile automation options, intuitive programming, and seamless robotic integration for large and small tasks. Reviews highlight ease of use and operational safety.

-

Amada ENSIS : Specializes in hybrid laser AND fiber units ideal for complex metal assemblies; offers fast cycle times and high-quality welds with minimal distortion. Users appreciate the multi-material compatibility.

-

Coherent Laser Machines : Strong on customization—offering turnkey welding solutions for micro-welding, polymer welding, and even additive manufacturing applications. Widely praised for application engineering and support.

People Also Ask: Frequently Asked Questions About Automated Laser Welding

What is automated laser welding and how does it differ from manual welding?

-

Automated laser welding utilizes computer-controlled laser systems to join materials with precise, repeatable results. Unlike manual or traditional welding systems, automated laser welding offers higher speed, reduced human error, and consistent weld quality, which results in significant time and cost benefits for manufacturers.

How can automated laser welding help reduce operational costs?

-

By minimizing labor, improving material utilization, reducing energy consumption, and decreasing scrap rates, automated laser welding systems can substantially lower the overall cost per part.

Is automated laser welding suitable for small or custom manufacturers?

-

Automated laser welding is highly adaptable and can be configured for small-batch production, custom projects, and prototyping, making it an excellent solution even for smaller manufacturers seeking efficiency and flexibility.

Benefits and Limitations: Making Automated Laser Welding Work for You

-

Benefits: Dramatic efficiency boost, superior accuracy and repeatability, rapid speed, lower labor costs, reduced waste, greater product consistency, and flexible integration with robotics.

-

Limitations: Higher initial capital investment, need for technical training, integration complexity for legacy equipment, and regular maintenance/calibration of optical components.

With labor expenses and tariff pressures mounting overseas, reshoring production is becoming more attractive—and automated laser welding makes it practical. Advanced laser system integration supports the shift back onshore by minimizing labor needs, raising efficiency, and maintaining the highest weld quality standards. Video case studies show how manufacturers have cut costs and delivery times, thriving in North America’s more responsive supply chains.

Expert Answers: Most Common FAQs on Automated Laser Welding Systems

Which industries benefit the most from automated laser welding solutions?

-

Industries such as automotive, aerospace, electronics, and medical device manufacturing achieve the greatest efficiency and quality improvements with automated laser welding systems.

Can automated laser welding systems integrate with robotics and smart manufacturing?

-

Yes, most modern automated laser welding systems support integration with robotics, vision systems, and smart factory controls for end-to-end automation.

Why Now: The Business Case for Switching to Automated Laser Welding

"Switching to automated laser welding was the single most cost-effective decision we made in the last decade." – Director of Manufacturing, TechParts Inc.

The fast-changing tariff and supply landscape makes cost-effective, high-quality onshore production more essential than ever. Automated laser welding gives companies the speed, control, and quality needed to outperform global competition—securing your market position for years to come.

Start Saving Today: Get a Quote for Automated Laser Welding Solutions

-

Facing Tariff Pressures? It’s Time to Reshore Smarter. At Electronic Service Products, we specialize in precision laser machining solutions that meet the highest quality standards—onshore, on time, and on budget. Whether you're looking to reshore your manufacturing or avoid the mounting cost of overseas tariffs, we offer the speed, precision, and flexibility your supply chain demands. Call today 203-265-4167 or go to espcnc.com/request-a-quote

Take action: Reach out today to request a customized quote and discover tailored savings with advanced automated laser welding.

Automated laser welding is revolutionizing manufacturing by enhancing precision, efficiency, and cost-effectiveness. For a comprehensive understanding of this technology, consider exploring the following resources:

-

“Automated Laser Welding: What You Need to Know” ( laserax.com ) provides an in-depth look at automation tools such as SCARA robots, inline weld monitoring systems, and remote welding heads, illustrating how these components contribute to improved weld quality and production efficiency.

-

“LightWELD® Cobot System | Welding Automation Made Easy” ( ipgphotonics.com ) introduces a collaborative robot laser welding system designed to automate various welding tasks, enhancing productivity and allowing skilled welders to focus on more complex projects.

These resources offer valuable insights into the benefits and applications of automated laser welding systems, helping you make informed decisions about integrating this technology into your manufacturing processes.