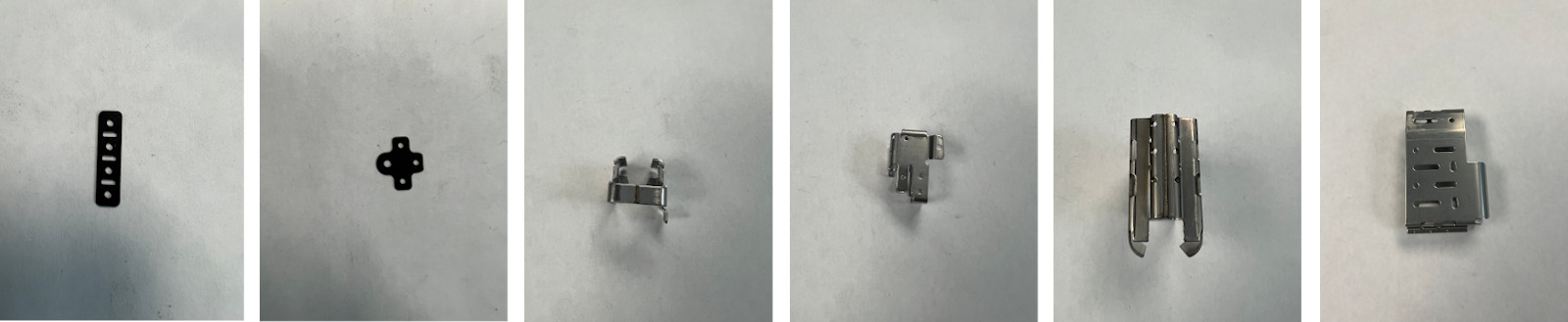

Revolutionize Production with Cutting-Edge Laser Welding Technology

Did you know? In just one year, over 35% of advanced manufacturing facilities worldwide adopted laser welding technology to accelerate production, marking a dramatic shift towards precise, high-efficiency manufacturing . As global industries race toward smarter automation, laser welding stands at the forefront—offering unmatched speed, accuracy, and adaptability.