| 126 South Turnpike Road Unit 2 Wallingford, CT 06492 |

|

Call Today! 203-265-4167   |

Stay Ahead with Laser Welding Industry Trends You Can't Ignore

Did you know? The global laser welding machine market is on track to exceed $5 billion by 2028. As precision-focused laser welding systems swiftly overtake traditional welding machines, energy efficiency and automation now define the future of industrial welding. If you want your manufacturing to thrive, monitoring laser welding industry trends is non-negotiable! In this comprehensive guide, you'll learn what’s shaping the welding machine market , which innovations to adopt first, and exactly how you can position your business to win in the new era of welding tech .

Unveiling the Laser Welding Industry Trends: Why Staying Updated Matters

-

Did you know the global laser welding machine market is projected to reach over $5 billion by 2028?

-

Traditional welding machines are giving way to precision laser systems at an unprecedented rate.

-

Energy efficiency and automation are redefining the welding tech landscape.

The laser welding industry trends highlight a powerful transition from conventional welding approaches to cutting-edge, highly automated laser welding machine systems. Businesses that keep pace, invest in the latest fiber laser systems , and adopt eco-friendly production practices consistently outperform their competitors. The welding machine market is evolving quickly—fueled by demand for faster production, heightened precision in the manufacturing process , and the unique capabilities of laser welding machines in sectors like automotive and medical devices. Staying ahead is about more than buying the newest machines; it means understanding global laser shifts, market forecast periods, and the integration of AI into your welding solutions .

Laser Welding Industry Trends Shaping the Welding Machine Market

Advancements in Laser Welding Technology

-

Introduction of new laser welding machines

-

Emergence of fiber laser welding systems

-

Enhanced energy efficiency and sustainability

Advancements in laser welding technology are transforming manufacturing. The latest fiber laser systems offer superior speed, control, and adaptability, enabling more precise joins and reducing errors compared to traditional welding machines . Automation is a key driver: factories are integrating AI-powered controls with laser welding machines to monitor quality in real-time, quickly adapt to new production runs, and lower the cost per weld.

The rise of energy-efficient laser welding machines and more sustainable welding processes is also crucial. These machines help manufacturers reduce their carbon footprint, comply with evolving regulations, and lower operating costs. For businesses aiming for long-term growth, adopting these laser systems is rapidly becoming best practice.

Growth of the Global Laser Welding Machine Market

-

Key drivers and inhibitors in the machine market

-

Regional trends: North America and global laser growth

The global laser welding machine market is being propelled by several factors: soaring demand for high precision, a skilled labor shortage that favors automation, and a rise in complex product manufacturing. North America remains a massive innovation hub, but Asia-Pacific is rapidly expanding due to robust automotive and electronics sectors. Challenges like high initial investment and volatile global supply chains exist but are increasingly offset by falling equipment costs and the promise of greater productivity.

Regional differences matter: while North America drives early-stage adoption of AI and advanced analytics in welding tech , Asia-Pacific leads in high-volume output and rapid scaling of laser welding machines . By tracking these laser welding industry trends , manufacturers can target the best markets, plan for the forecast period , and invest wisely in global expansion.

Impact of Laser Welding on the Automotive Sector and Medical Devices

-

Automotive sector adoption of laser welding processes

-

Influence on medical device manufacturing and innovation

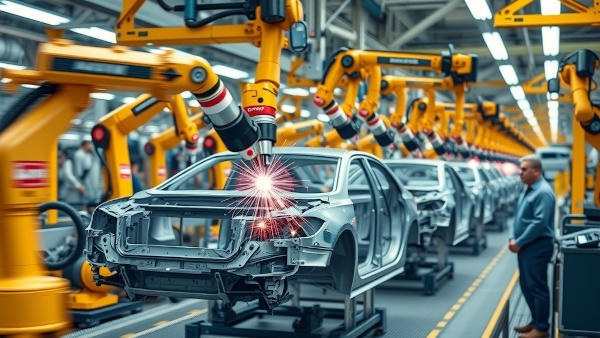

The automotive sector stands at the forefront of laser welding industry trends . Advanced laser welding processes allow carmakers to create lighter, more durable vehicles, essential for fuel efficiency and electric vehicle transition. Automated robotic cells fitted with fiber laser tools enable rapid, repeatable welding of tough new alloys—a core requirement in today’s evolving automotive landscape.

In medical device manufacturing, laser welding machines produce ultra-precise, sterile joins—key for producing implants, surgical tools, and wearables. As regulatory standards toughen, the ability to repeatedly create micro-welds that meet strict specs is driving medtech’s rapid adoption of laser welding . Manufacturers that capitalize on these laser welding industry trends find themselves at the leading edge of two of the world’s most lucrative markets.

The Future of the Laser Welding Market — Forecast Period and Innovations

Laser Welding Market Forecast and Revenue Projections

-

Insights into future forecast period

-

Revenue breakdown of welding machine market and global laser welding machine market

The forecast period through 2028 holds robust promise for the laser welding machine market . Market researchers predict revenues will soar past $5 billion globally , fueled by the transformation of the welding market from traditional engines to highly automated, digitally connected factories. Medical devices, automotive, and electronics manufacturing will yield the highest laser welding machine sales, with new applications in battery production and aerospace following closely behind.

Leaders in the welding machine market are already pivoting, launching modular and compact laser welding solutions tailored for diverse environments—from microelectronics labs to sprawling automotive lines. Those businesses prepared to act, invest, and innovate ahead of the curve will command a disproportionate share of future laser welding market growth.

Emerging Laser Welding Applications in Key Industries

-

Expansion into automotive, medical device, and electronics sectors

-

Role of energy efficiency in driving industry adoption

Laser welding industry trends reveal growing adoption in three primary sectors: automotive, medical devices, and electronics. In automotive, high-strength steel and lightweight alloys for electric vehicles benefit from fiber lasers that can weld tough materials with greater reliability and less post-processing. In medical device production, laser welding machines make miniature, flawless welds essential for safe and reliable products.

Energy efficiency continues to drive interest, particularly as companies look to meet global sustainability standards and reduce manufacturing costs. With laser welding systems , manufacturers achieve faster cycle times, less material waste, and lower energy consumption compared to traditional welding machines. This shift to cleaner, smarter manufacturing is a cornerstone of future welding tech .

Comparing Traditional Welding Machines vs. Laser Welding Machines: Efficiency, Speed, and Cost

| Feature | Traditional Welding Machines | Laser Welding Machines |

| Precision | Moderate | High (micron-level) |

| Speed | Slower; multi-step | Faster; single-pass |

| Material Range | Limited (mostly metals) | Wide (metals, plastics, alloys) |

| Automation Compatibility | Low–Moderate | High |

| Energy Consumption | High | Lower (energy efficient) |

| Typical Cost* | Low initial, high maintenance | Higher initial, lower long-term |

*Costs vary based on application, scale, and integration level.

Challenges and Opportunities in the Laser Welding Industry Trends

Facing Tariff Pressures and Global Supply Chain Shifts

-

The impact of overseas tariffs on the welding machine market

-

Why companies are reshoring manufacturing and investing in laser welding machines

As global tariffs increase the cost of imported welding machines and components, manufacturers are compelled to reevaluate sourcing strategies. Many are choosing to reshore or nearshore production, investing in advanced laser welding machines to secure supply chains, reduce logistics risks, and benefit from tighter production control. This transition not only circumvents tariff issues but also allows businesses to swiftly embrace the latest laser tech innovations—putting local production on par with global competitors.

The welding machine market is entering a new era, where companies agile enough to transition back to domestic manufacturing, or diversify suppliers, stand to gain a strategic advantage in both cost and operational resilience. Following these laser welding industry trends helps manufacturers adapt to changing global dynamics without losing their competitive edge.

Sustainability and Energy Efficiency in Laser Welding Tech

-

How energy efficiency is shaping laser welding market growth

-

Innovations in eco-friendly welding processes

Sustainability has become more than just a buzzword; it's now an operational imperative. The shift to energy-efficient laser welding processes not only addresses environmental regulations but also generates significant cost savings over time. Innovations like smart energy management, real-time process feedback, and green design principles are now built into leading laser welding machines .

As eco-friendly laser welding becomes standard, businesses that invest in green technologies see faster returns. This focus on sustainability is helping to position laser welding industry trends at the very center of a rapidly transforming manufacturing market.

Expert Insights: Quotes on Laser Welding Industry Trends

"Laser welding tech is redefining manufacturing efficiency across every sector. The future lies in precision, automation, and sustainability."

– Dr. Alex Kim, Global Laser Tech Analyst

People Also Ask: Laser Welding Industry Trends

How big is the laser welding market?

-

The global laser welding machine market was valued at approximately $4.3 billion in 2022 and is expected to surpass $5 billion by 2028, driven by advanced laser welding machines and increasing demand in the automotive and medical device sectors.

What is the future of the welding industry?

-

The welding industry is moving toward higher adoption of laser welding tech, automation, and energy-efficient solutions. The laser welding market forecast indicates steady growth, especially in precision-focused sectors.

What is laser welding mostly used in?

-

Laser welding is primarily used in automotive manufacturing, medical devices, aerospace, and electronics due to its high precision, speed, and capability to join complex materials.

How much does laser welding make?

-

Revenue from laser welding machine sales is estimated to reach over $5 billion globally, with top manufacturers seeing strong year-over-year growth as laser welding machines replace traditional welding processes.

Key Laser Welding Industry Trends in Every Welding Market Segment

-

Automation and smart manufacturing driving adoption

-

Fiber laser systems leading efficiency gains

-

Expansion into smaller, more flexible laser welding machines

Across every welding market segment , manufacturers are prioritizing automation and “smart factory” setups, using digital monitoring and AI to optimize every welding process . Fiber laser systems are now recognized for their exceptional efficiency, adaptability, and cost savings—leading to broader adoption, especially in high-mix, low-volume industries.

The market is also experiencing a surge in compact, modular laser welding machines suited for new product designs and evolving regulatory requirements. This flexibility helps manufacturers pivot between runs with minimal downtime, maximizing output and ROI.

Frequently Asked Questions about Laser Welding Industry Trends

-

What are the top benefits of using laser welding in manufacturing?

Laser welding delivers top-tier precision, excellent repeatability, high weld quality, and significant speed improvements over traditional methods. The process is highly energy efficient, easy to automate, and minimizes post-processing—making it ideal for industries aiming to produce more with less waste and fewer defects. -

How does the fiber laser differ from traditional welding machines?

Fiber lasers use thin optical fibers to focus and deliver the laser beam, resulting in higher energy efficiency, tighter beam control, and less maintenance than classic welding machines. This allows for cleaner welds, less material distortion, and more flexibility with diverse materials and applications. -

Is the laser welding machine market expected to grow faster than the overall welding machine market?

Yes—forecasts show the laser welding machine market growing significantly faster than the traditional segment, thanks to advancing technology, rising labor shortages, and the critical need for high-precision, sustainable manufacturing worldwide.

Comparing Laser Welding and Traditional Welding Machines: Which Leads the Market?

Laser Welding Machines vs Welding Machines: Speed, Cost, Precision, and Market Penetration

| Aspect | Traditional Welding Machines | Laser Welding Machines |

| Speed | Lower, multi-step process | Higher, faster welds |

| Cost Over Time | Low upfront but higher ongoing costs (maintenance, labor) | Higher initial, lower maintenance and labor costs |

| Precision | Variable, less consistent | High precision (micron scale) |

| Market Penetration | Declining in high-tech sectors | Rapidly increasing, especially in automotive, medical, and electronics |

Best Practices for Adopting Laser Welding Industry Trends in Manufacturing

-

Audit your current welding processes and identify areas for automation.

-

Invest in energy-efficient laser welding machines.

-

Leverage expert partners to help with the transition from conventional to fiber laser welding solutions.

-

Monitor the global laser welding machine market for emerging devices and best-in-class performance.

-

Reshore or diversify your supply chain to mitigate tariff-related risks.

By systematically assessing your manufacturing process , investing in proven fiber laser solutions, and working with experienced implementation partners, your business can more easily transition to next-gen laser welding systems . Keeping a close eye on the machine market for emerging trends and reshoring strategies also helps you minimize risk in unpredictable market environments.

Case Studies: Laser Welding Industry Trends in Action

-

Automotive sector replacing traditional welding with high-speed laser systems

-

Medical device manufacturers using laser welding to increase product precision and reliability

Multiple case studies illustrate real-world success with laser welding industry trends . Leading automotive manufacturers have adopted high-speed fiber laser systems, replacing outdated processes to weld lighter car bodies that improve vehicle range and safety. This shift has reduced cycle times, cut costs, and enabled the production of new electric vehicles at scale.

In the medical space, manufacturers rely on laser welding solutions to deliver precision welds for implants and miniature devices. These joins meet strict regulatory standards and are crucial for ensuring the long-term reliability required in life-saving applications—a compelling motivator for ongoing investment in laser welding market tech.

The Role of Global Laser and Fiber Laser Systems in Welding Tech Advancement

-

How global laser welding and fiber technology are rewriting the standards for the welding machine market

-

Applications beyond automotive and medical devices: electronics, aerospace, and more

Global laser and fiber laser systems have fundamentally changed the rules for the welding machine market . As these technologies spread, industries like aerospace and electronics benefit from their ability to join dissimilar or delicate materials with previously unattainable finesse. The global laser welding movement is driven by continuous improvement: shorter wavelength lasers, smarter beam delivery, and deep integration with smart factory systems.

Moving beyond just automotive and medical devices, fiber lasers now power advancements in battery production, semiconductors, and even consumer electronics—reinforcing how essential monitoring and acting on laser welding industry trends has become for any forward-thinking manufacturer.

Top 10 Actionable Trends in the Laser Welding Industry Market

-

Rise of fiber laser welding systems

-

Adoption of AI and automation in welding tech

-

Increased demand for compact laser welding machines

-

Enhanced energy efficiency

-

Modular machine designs

-

Focus on medical devices and automotive sectors

-

Rapid growth in North America and Asia-Pacific

-

Adoption of green manufacturing processes

-

Expansion of reshoring and nearshoring strategies

-

Digital transformation in welding process monitoring

These laser welding industry trends are actionable and essential for companies seeking to stay ahead. From adopting fiber laser systems to embracing AI-driven welding tech , businesses can strengthen market position and improve operational resilience.

Summary of Essential Laser Welding Industry Trends You Can’t Afford to Miss

-

Precision, automation, and energy efficiency define the future of laser welding

-

Market growth accelerates amid global supply chain and tariff challenges

-

Smart adoption strategies are key for manufacturing success

Ready to Upgrade? Reshore Your Manufacturing with Cutting-Edge Laser Welding Solutions

Facing Tariff Pressures? It’s Time to Reshore Smarter. At Electronic Service Products, we specialize in precision laser machining solutions that meet the highest quality standards—onshore, on time, and on budget. Whether you're looking to reshore your manufacturing or avoid the mounting cost of overseas tariffs, we offer the speed, precision, and flexibility your supply chain demands. Call today 203-265-4167 or go to espcnc.com/request-a-quote

Ready to lead the market? Review your welding strategy, invest in energy-efficient laser welding machines , and start building the smart, resilient future your business deserves.

To deepen your understanding of the latest developments in laser welding, consider exploring the following resources:

-

“The Future of Laser Welding Machines: Trends and Innovations in the Industry” ( shop.adhmt.com )

This article delves into cutting-edge advancements such as beam shaping, adaptive optics, and AI-powered control systems, highlighting how these innovations are enhancing precision and efficiency in laser welding applications.

-

“Laser Welding Machine Market Will Evolve by 2032” ( marketsandmarkets.com )

This report provides a comprehensive analysis of the projected growth and transformation of the laser welding machine market, emphasizing the integration of AI, robotics, and green technologies, and their impact on various industries.

By engaging with these resources, you’ll gain valuable insights into the technological advancements and market dynamics shaping the future of laser welding.